Separation Technology

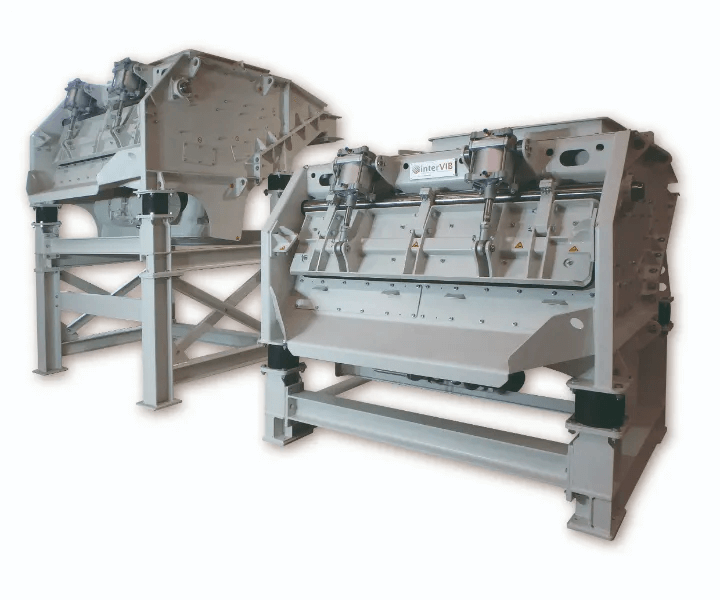

With separation technology from interVIB, you can reliably separate and classify bulk materials according to size and shape. Our high-performance solutions ensure clean and efficient material processing and thus make a decisive contribution to the quality and efficiency of your processes.

interVIB can separate your bulk material into numerous fractions. This will be achieved by multi-deck screening machines which results more than two fractions. This way the oversized and the fines get separated and the required granulation can be processed easily.

Separation Technology made by interVIB

Our separation technology solutions offer you reliable systems for the precise separation and classification of a wide range of bulk materials. Whether Continuous Shake Out SOC, Vibratory Lump Breaker LB or Vibratory Screen VS – each product is specially developed to ensure precise and clean separation even at high throughput rates.

Classification Technology

Classification technology enables the precise separation of bulk materials according to grain size. Devices such as Vibratory Screens VS and Continuous Shake Out SOC are used to sort materials into different fractions, which is of great importance in the building materials and recycling industries. Other industries in which classifying technology is used are

Coffee grounds, lumps in sugar or salt, stones from sand, field beans, plastic shreds or pellets, animal feed pellets, flour and sewage sludge.

Precise classification ensures that only materials of the desired size are processed.

Breaking Technology

The pulverizing technology is used to process caked or lumpy materials and is an essential step before the actual separation.

We offer you Continuous Shake Out SOC and Stationary Shake Out SOS to separate castings and molding sand, furan-bonded or inorganic, from each other.

The Vibratory Lump Breaker LB grinds cast sand lumps or similar caked bulk materials using vibration technology.

Frequently asked questions about Separation Technology

Can’t find the answer you are looking for?

Please contact our customer support team.

What is separation technology and what is it used for?

Separation technology is used to separate materials according to their properties such as size, weight or density. It is used in industries such as recycling, construction, chemicals and food production to efficiently sort, clean or recycle materials. With our machinery, we focus exclusively on separation by size.

What are different types of separation technology?

Common processes include vibratory screens, magnetic separators and float-sink processes. Each system is build tailor-made to specific requirements and materials.

How does a vibratory separator work?

A vibratory separator uses vibrations to move and separate materials on a screen or conveyor deck. Fine particles fall through the mesh of the screen, while larger particles remain on the deck and are transported further.

Which materials can be processed with separation technology?

Separation technology can be used to process numerous materials, including plastics, glass, metals, sand, gravel and organic materials such as compost or wood waste.

What are the advantages of the separation technology from interVIB?

Our separation machinery is efficient, precise and durable. It can be individually adapted and are characterized by low maintenance costs and a high processing capacity.

We are guaranteed to find the right screening surfaces for your application – whether steel mesh, rubber or plastic surfaces, bars or ribs, lamellas or 3D surfaces.

How can I improve the separation performance of my machine?

The separation performance can be optimized by adapting the screen geometry, selecting the right separation technology and fine-tuning the operating settings. Our experts will be happy to help you analyze and improve your systems.

What capacities can separation machinery from interVIB handle?

Our separation machinery is designed for a wide range of capacities, from small quantities in laboratory applications to several thousand tons per hour in industrial processes. We customize each machine to your requirements.

Is separation machinery also suitable for damp or sticky materials?

Yes, our machinery is specially designed to process even demanding materials such as moist or sticky substances. We offer options such as de-watering screens or machinery with non-stick coatings.

How maintenance-intensive is separation machinery from interVIB?

Our machinery is designed to be particularly low-maintenance. However, regular inspections of wearing parts such as screening surfaces ensure a long service life and optimum performance.

Can separation machinery be integrated into existing production systems?

Yes, our separation machinery can be flexibly integrated into existing systems. We offer tailor-made solutions to fit the machinery perfectly into your production lines and optimize your workflow.